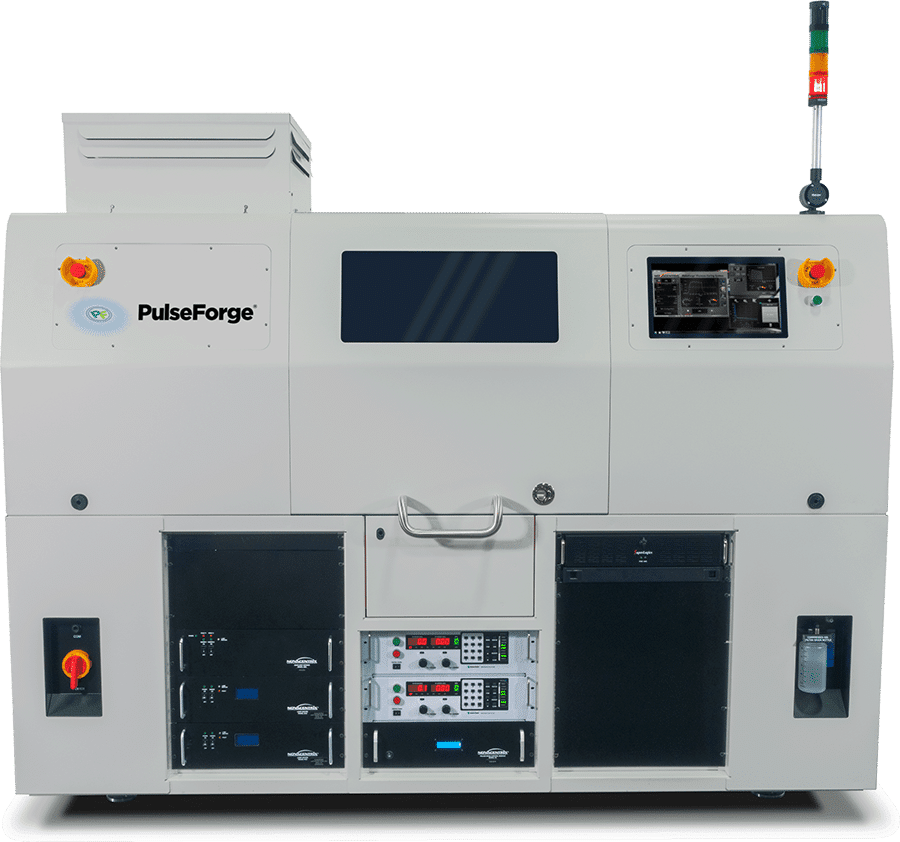

In-Line Thermal Processing

With substantially higher throughput, PulseForge In-Line revolutionizes electronics manufacturing.

Unrivaled processing times and highest throughput in SMT and PCB manufacturing

With the slow processing times of ovens, and one-terminal-at-a-time coverage limitations of lasers, current thermal processing solutions in microelectronics manufacturing are an expensive bottleneck.

Powerful and configurable, PulseForge Soldering In-Line’s high-intensity pulsed light solution erases those limitations – without damaging previously off-limits heat-sensitive components and substrates.

Unrivaled processing times and highest throughput in SMT and PCB manufacturing

With the slow processing times of ovens, and one-terminal-at-a-time coverage limitations of lasers, current thermal processing solutions in microelectronics manufacturing are an expensive bottleneck.

Powerful and configurable, PulseForge Soldering In-Line’s high-intensity pulsed light solution erases those limitations – without damaging previously off-limits heat-sensitive components and substrates.

Process in milliseconds

not minutes

- Temperature selectivity means no damage to heat-sensitive materials and components (including sensors and batteries)

- Flashlamps wide area enables multiple board level processing

- Proprietary uncollimated light allows for processing on curved surfaces

- Immediate on/off cycle translates to no idle time

Designed for high throughput processing

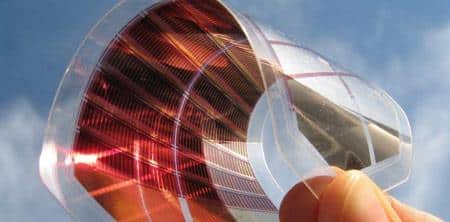

What if you could cure, sinter, and solder on paper, plastic, fabric, or recycled materials? What if you could process ITO for glass, PET, or organic materials? What if you could debond without ash or chemicals? What if we could completely reimagine the thermal process to push innovation and technology while increasing speed, reducing cost, and reducing impact on the environment?

With PulseForge Digital Thermal Processing…you can!

Papers

Fabrics

Thin Glass

Plastics

Perovskite solar cells

Find the PulseForge In-Line that best meets your individual needs