SALMONELLA

CAMPYLOBACTER

ENTEROBACTER

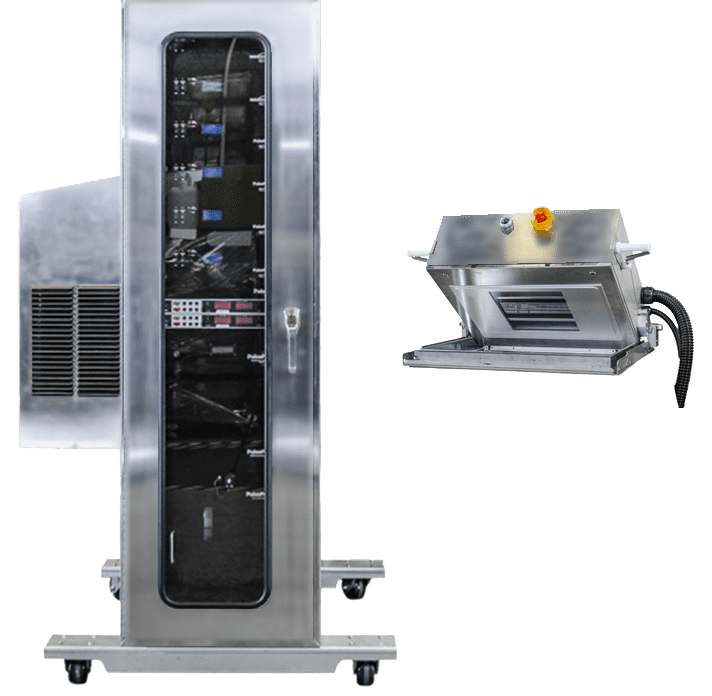

Over Conveyor Configuration

Process

- Designed for 3–6 J/cm2 (Total Optical Energy) delivered to target surface at 100 feet per minute

- Designed for 1 kW/cm2 (Peak Optical Intensity) delivered to target surface

Description

- 2x 12” x 12” Flash Heads in drop-through processing chute

- 4 Lamp Drivers (2 per Flash Head)

- Up to 40kW Shared Power Supply

- Entire Floor System is NEMA 4X

Features

- Floor Operation through Simple Control Box

- Remote (Off Floor) System Enable & Programming through Client PC

- Responsive to Floor Control Signals {CO, QE, CP}

- System Active if Conveyor On (CO) & Chicken Present (CP) Asserted

- Firing Rate Driven by Quadrature Encoder (QE)

- Line Rates in excess of 100 feet per minute (FPM)

- Real Time Fault Monitoring & Alarms

- TCP API Available for Direct Machine Interface

Dimensions

- Equipment Rack: 24” (W) x 42” (D) x 78” (H) [+4” (H) Stabilization Plate or Casters]

- Floor Footprint: 48” (W) x 90” (D)

- Flash Head: 24” (W) x 30” (D) x 12” (H)

Safe, Reliable, Configurable Decontamination

The food supply chain is constantly battling pathogens such as Listeria, Campylobacter, Salmonella, Enterobacter, and E. coli that contaminate food products during processing.

It’s Safe: The PulseForge Photonic Decontamination System (PDS) effectively reduce population counts spoilage and pathogenic microorganisms in accordance with 21 CFR 179.41, while avoiding excessive heat that may harm food or packaging materials. Adding the PulseForge PDS to the production process can minimize the need for harsh chemicals.

It’s Reliable: Utilizing 20 years of experience in high-speed production systems, the PulseForge PDS is the next-generation of water cooled pulsed light decontamination. It is designed for washdown environments and can keep up with fast-paced high-volume food processing while delivering rapid, dependable results.

It’s Configurable: The PulseForge PDS has a modular design, enabling easy and effective integration with existing lines, to provide decontamination at crucial points. It’s also scalable for different processing speeds and product decontamination profiles.

Components

Specs and Supporting Information

Are you ready to discover the impact of pulsed-light decontamination?