Integrated Thermal Processing

Integrate Digital Thermal Processing™ into your manufacturing environment with the PulseForge Embed.

Eliminate Waste

Increase Efficiency

The modular design of the PulseForge platforms enable you to bring processes and validations from R&D into production seamlessly. All of the configurations and application areas that the R&D tool can support across curing, sintering, soldering, drying, crystallization, and reduction can be deployed as an integrated solution into your manufacturing environment. This enables you to deploy Digital Thermal Processing in a way that best meets your needs.

Designed for application development and full-volume production

Digital Thermal Processing configurations can be integrated into EMS, glass, semiconductor environments as well as being set up to support roll- to-roll and conveyor-based materials processing and full volume production for multiple industries.

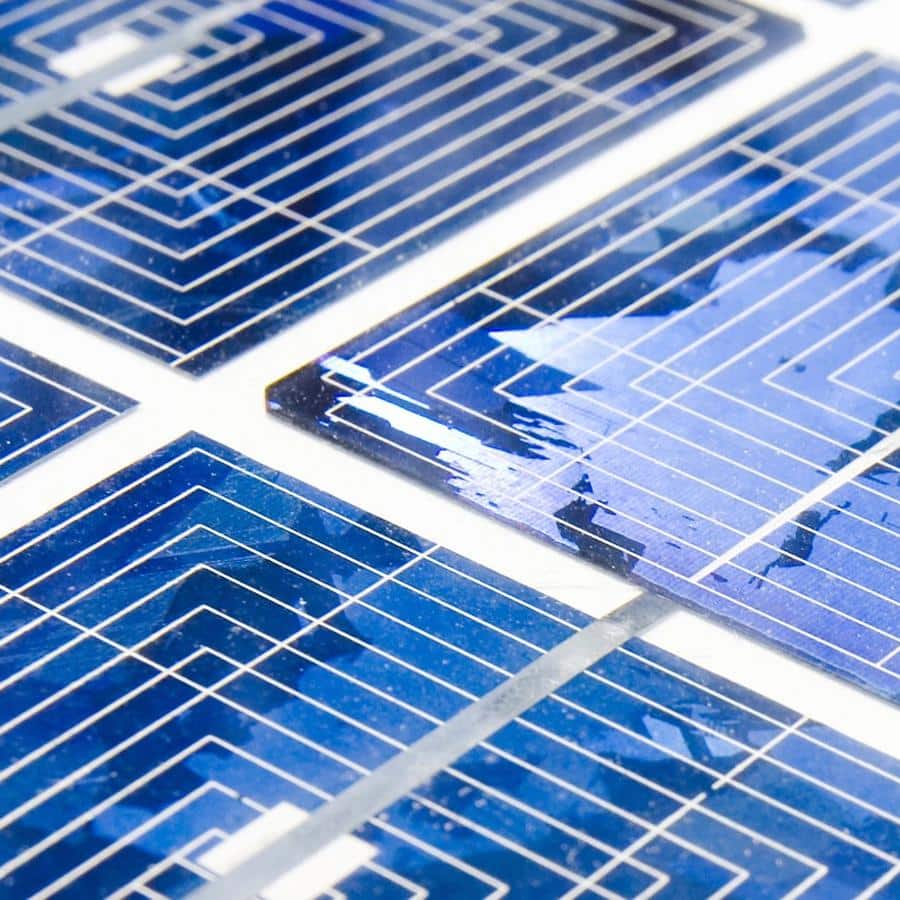

Delivering maximum peak power

PulseForge Integrated Thermal Processing delivers maximum peak power – the type of power needed to achieve very-high surface heating of the target semiconductor materials – without damaging underlying, low- temperature substrates.

With our proprietary flashlamp technology, the PulseForge Embed gives you:

- Exposures as short as 30 microseconds

- Exact control of voltage and current

- Successful processing conditions

- Freedom to choose heat-sensitive, inexpensive substrates, including plastic and paper

Find the PulseForge Embed that best meets your individual needs