Photonic soldering makes this possible with extremely rapid heating over extremely short time scales. Heating occurs via optical absorption of intense white light at the top surface of the PCB. The heating rate is fast — much faster than the rate of heat conduction throughout the PCB. This results in a local build-up of heat within the solder paste, so that reflow begins and ends before the temperature ever has a chance to equalize throughout the PCB composition. And because the heating is localized, the total thermal energy delivered by photonic soldering is small — just enough to reflow small quantities of solder, and not enough to damage components.

Now, however, direct soldering of tabbed batteries is possible with photonic soldering. Similarly, temperature-sensitive sensors and other specialized components can also be attached using a wide range of solder alloys. In addition, photonic soldering allows flexible cables and wires to be soldered directly to circuit boards and other components without the traditional headers and connectors, further reducing product size, weight, and cost.

Low-temperature substrate materials are another exciting possibility for PCBs assembled with photonic soldering. This includes a diverse range of plastics, 3D-printed materials, recycled materials, paper, fabric, and glass. The range of possible benefits are equally diverse — weight reduction, cost, optical transparency, recyclability, and mechanical flexibility are just a few of the most compelling examples.

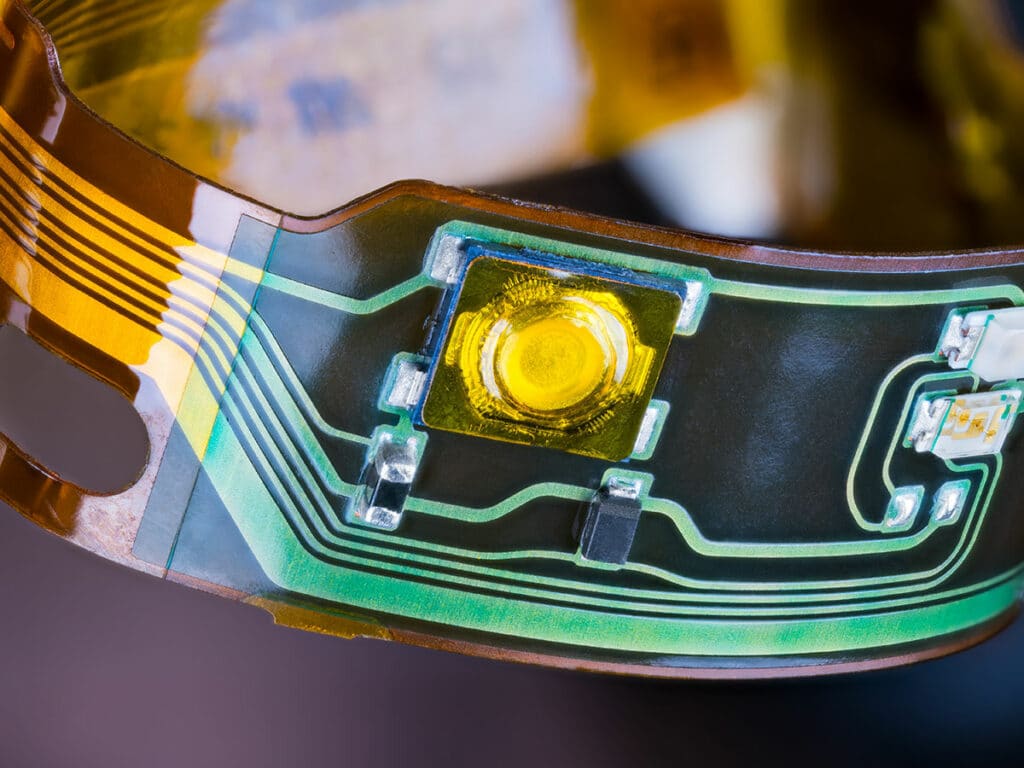

Mechanical flexibility, in particular, is worth a closer look. Flexible film substrates, such as polyimide, enable the functionality of a PCB to be integrated into the form of a product. The resulting space and weight savings, not to mention the aesthetic benefits, find wide applicability in consumer electronics, wearables, lighting, and numerous automotive, aerospace, industrial, and medical applications.

Photonic soldering makes it possible to assemble circuits on many types of flexible substrates that cannot survive conventional reflow processes. One particularly useful example is PET, the same plastic used to make soft drink bottles and rigid food packaging. As a thermoplastic, PET is easy to form and process, and can be recycled. PET is strong for its weight, and optically transparent, which makes it especially appealing for lighting applications.