PulseForge Photonic Curing Blog Articles

What is PulseForge Soldering, and Why Use it?

Choosing the appropriate technologies for your electronics assembly line is essential. And from board design to product reliability to the production capacity, the reflow step is a critical part of that choice.

Benchmarking Flashlamp Output

There is a speed limit to a human’s light detection abilities. If something happens faster than approximately 60 Hz, our brains will tie those episodes together and treat them as one longer event. This phenomenon is used ubiquitously by the motion picture industry to create perception of movement from still

PulseForge processing of 3D printed devices with conductive filaments

3D printing and sintering, or additive manufacturing, has seen commercial efforts over several decades with a quick rise in interest over the past several years. A Gartner analysis from 2019 showed a 300% growth in enterprise 3D printer manufacturers over the preceding 3 years.

The evolution of photonic curing

Photonic curing is the high temperature processing of thin films using a flashlamp. When this processing is performed on a low temperature substrate, such as plastic or paper, a significantly higher temperature can be attained in the film versus an oven without damaging the substrate.

PulseForge tools enabling the production of perovskite solar cells

The light-absorbing nature of perovskites enables extensive use of photonic curing to fabricate and/or improve these materials.

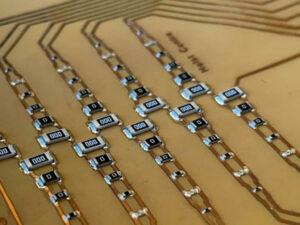

Photonic curing and soldering

Light energy incident on a body will be absorbed and heat up the object. The light-matter interaction determines what fraction of light is reflected back, transmitted through or absorbed by the body.