Sustainable Manufacturing Example

Reduced Energy Consumption

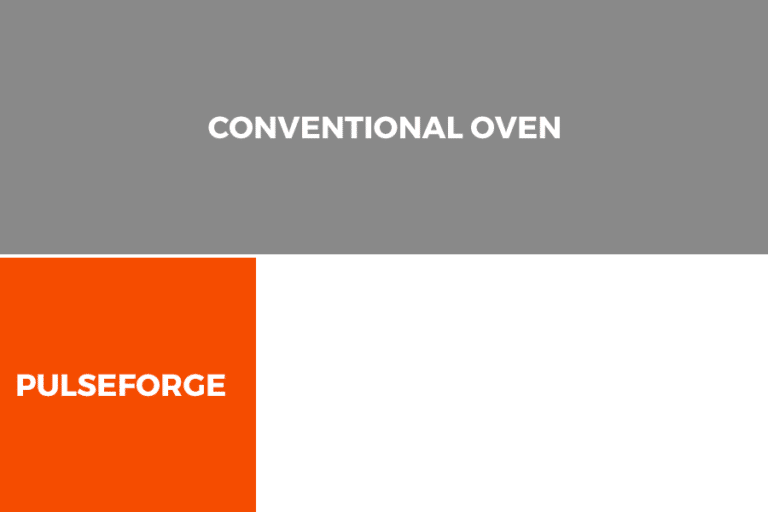

PulseForge’s Digital Thermal Processing™ saves energy when compared to other traditional processing methods.

Did you know?

But not with PulseForge!

An energy savings of 85%*

Reducing CO2 emissions by 318,000 lbs annually!

*Represents a specific, typical use case. Results may vary, depending on reflow ovens utilized, duty cycle process requirements, and materials.

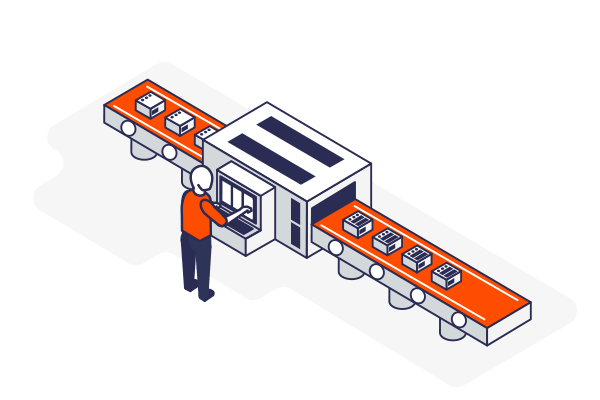

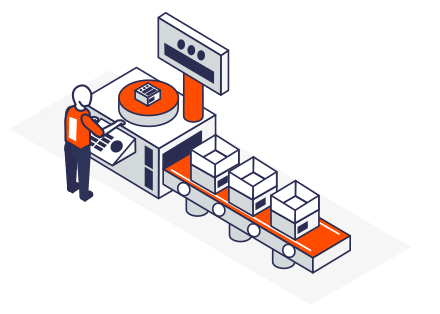

Reduced Physical Footprint

PulseForge Soldering In-Line requires one-third of the space on your manufacturing floor, when compared to a standard reflow oven.

How Do We Do It?

Reduced HVAC costs

No heating of the workplace environment means no additional load on expensive HVAC.

No Sustained Heat

Our pulsed-light technology heats up only when it’s processing.

No Warm Up Needed

Simply switch it on and PulseForge is ready to go.

No cool down

PulseForge does not radiate external heat.

Speed

Higher throughput microseconds processing, with 85% less energy consumption.*

How can we help your manufacturing become more energy efficient?

Fields marked with an * are required