Sustainable Manufacturing

We Take Our Role in

Global Ecology Seriously

Global Ecology Seriously

Find out how PulseForge’s products can help reduce your carbon footprint and improve your processing efficiency.

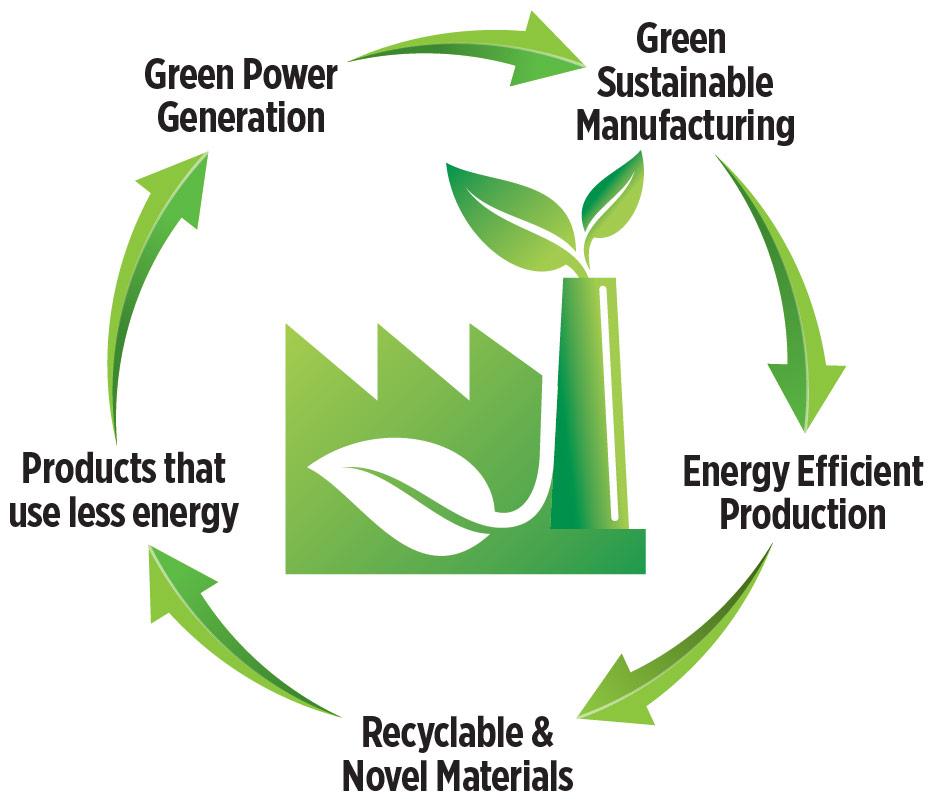

The PulseForge Green Advantage Cycle

Digital Thermal Processing™ is the sustainable manufacturing solution that offers real improvement in capabilities with no downsides.

PulseForge tools use only a fraction of the energy used by traditional thermal processing methods. This

energy savings spans a wide range of applications where Digital Thermal Processing is applicable including photovoltaics manufacturing, glass and coatings processing, and electronics production. That’s great, and on their own each application and opportunity is quite compelling. But when we step back and look at the bigger picture, we find that these applications link together and become truly impactful not just for specific markets, but for the planet and all of us who live here.

Power Generation & Storage

PulseForge tools are being used to develop more efficient and inexpensive photovoltaics such as CIGS and perovskites. Reduced heating means novel materials, and designs, for energy storage are feasible. This also significantly reduces the energy payback time compared to conventional solar cells.

PulseForge tools are being used to develop more efficient and inexpensive photovoltaics such as CIGS and perovskites. Reduced heating means novel materials, and designs, for energy storage are feasible. This also significantly reduces the energy payback time compared to conventional solar cells.

Sustainable Manufacturing

Calls to decarbonize the supply chain are growing louder, for good reason. Comprehensive in its inclusion, sustainable manufacturing encompasses

consideration of energy,

water, and materials. Digital Thermal Processing brings manufacturers options to improve resource selection

and utilization.

Energy Efficient Production

Case studies have shown that the PulseForge tools with Digital Thermal Processing use 15% or less of the direct energy used by traditional thermal processing, through heating of desired materials and limiting collateral heating. But think of the indirect savings as well – virtually no waste heat means reduced HVAC burden and limited/no cooling air flow. PulseForge Digital Thermal Processing enables sustainable manufacturing of your most advanced designs, with no downsides.

Case studies have shown that the PulseForge tools with Digital Thermal Processing use 15% or less of the direct energy used by traditional thermal processing, through heating of desired materials and limiting collateral heating. But think of the indirect savings as well – virtually no waste heat means reduced HVAC burden and limited/no cooling air flow. PulseForge Digital Thermal Processing enables sustainable manufacturing of your most advanced designs, with no downsides.

Products That Use Less Energy

Lighter materials, streamlined designs without additional connectors and fasteners, structural electronics combining form and function, well suited for mobility applications where mass moved is energy spent.

Lighter materials, streamlined designs without additional connectors and fasteners, structural electronics combining form and function, well suited for mobility applications where mass moved is energy spent.

Recyclable & Renewable Materials

Smarter, more limited use of thermal energy means more freedom in materials selection. Recyclable polymers can be used more often. Reduced need for harsh chemical solvents means more diverse organic materials can be selected. Additive manufacturing becomes a better choice.

Smarter, more limited use of thermal energy means more freedom in materials selection. Recyclable polymers can be used more often. Reduced need for harsh chemical solvents means more diverse organic materials can be selected. Additive manufacturing becomes a better choice.