Albuquerque, New Mexico – November 26, 2023 – Optomec, a trailblazing provider of additive manufacturing systems for printed electronics, and NovaCentrix, a global leader offering high-performance conductive inks for additive manufacturing, announce their strategic partnership to propel the additive manufacturing Industry. This long-standing collaboration has redefined the landscape of printed electronics by harnessing the combined expertise of both companies to deliver cutting-edge solutions across a diverse spectrum of industries.

Optomec’s groundbreaking aerosol jet printing technology has positioned the company as a leader in additive manufacturing. With proficiency in printing electronics, including sensors and components, on various substrates, Optomec delivers cost-effective, high-performance solutions across diverse industries such as aerospace, automotive, medical devices, and consumer electronics.

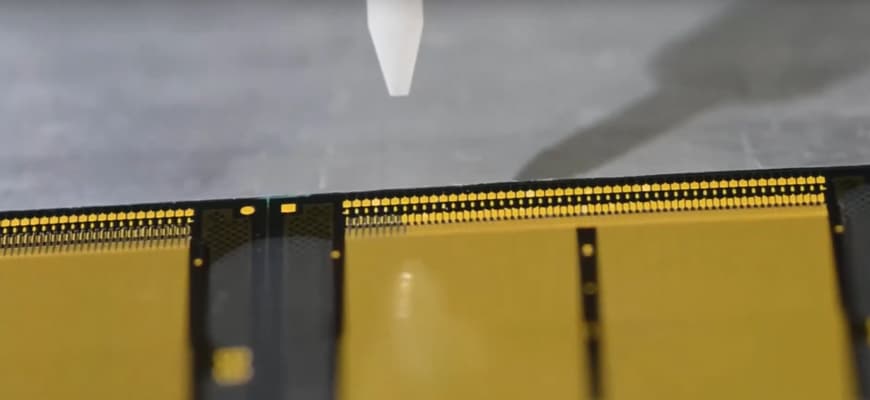

Complementing Optomec’s capabilities, Metalon® series inks by NovaCentrix, featuring silver, copper, gold and carbon variants, have established themselves as forefront choices within the industry for a wide range of applications. These highly versatile inks demonstrate exceptional suitability for printing on various substrates, including plastics (e.g., PET, polyimide), glass, metal, and paper. The collaboration between Optomec and NovaCentrix is poised to push the boundaries of additive manufacturing innovation, creating new possibilities for manufacturers.

A pivotal aspect of this partnership is the strategic collaboration designating Optomec as a “preferred partner” for supplying ink with their aerosol jet printers. As part of this collaboration, Optomec bundles NovaCentrix’s Metalon JS-A426 silver nanoparticle ink and other variants from NovaCentrix with their aerosol printers. This not only streamlines the procurement process for Optomec’s customers but also serves as a valuable training resource, enabling customers to effectively use the aerosol printer while utilizing the provided ink.

Robert Yusin, CEO of Optomec, says “The partnership with NovaCentrix has been longstanding and strategic. The ability to work closely with a materials vendor such as this helps us to deliver better output with our Aerosol Jet series of Printers. The combined offering of technology and materials gives us confidence in delivering industrial manufacturing solutions that can scale for mass production.”

Charles Munson, CEO of NovaCentrix, echoes the enthusiasm, stating, “The collaboration between NovaCentrix and Optomec is an exciting step forward for the printed electronics industry. Together, we will push the boundaries of what is achievable, empowering manufacturers to achieve new levels of performance and efficiency.”

Moreover, the collaboration extends to PulseForge, a spin-off from NovaCentrix and the leading provider of photonic curing equipment. PulseForge leverages intense pulsed light to rapidly cure and sinter inks for printed electronics, enhancing conductivity, reducing processing times, and lowering production costs. This pioneering technology swiftly transforms materials without jeopardizing the integrity of the underlying substrate, making it an ideal solution for various applications.

The partnership between Optomec and NovaCentrix promises to provide a groundbreaking solution for companies seeking to streamline their printed electronics manufacturing processes. By integrating aerosol jet printing with photonic curing, this collaboration will unlock opportunities for innovation and excellence in the ever-evolving domain of printed electronics.

About Optomec

A Digital Manufacturing system and software supplier offering Optomec’s patented Aerosol Jet Systems and DED metal printer technology.

About NovaCentrix

Considered the expert in next-gen printed electronics, for over twenty years, Austin, Texas, based NovaCentrix is the go-to leader for industry-transforming conductive inks and nanopowders. To learn more, please visit www.novacentrix.com.

About PulseForge, Inc.

PulseForge, Inc. utilizes applied energy in a precise and targeted manner to enable innovation in industrial manufacturing. Our expertise and tools empower our customers to explore novel materials and manufacturing methodologies, driving dynamic and efficient production at an industrial scale.